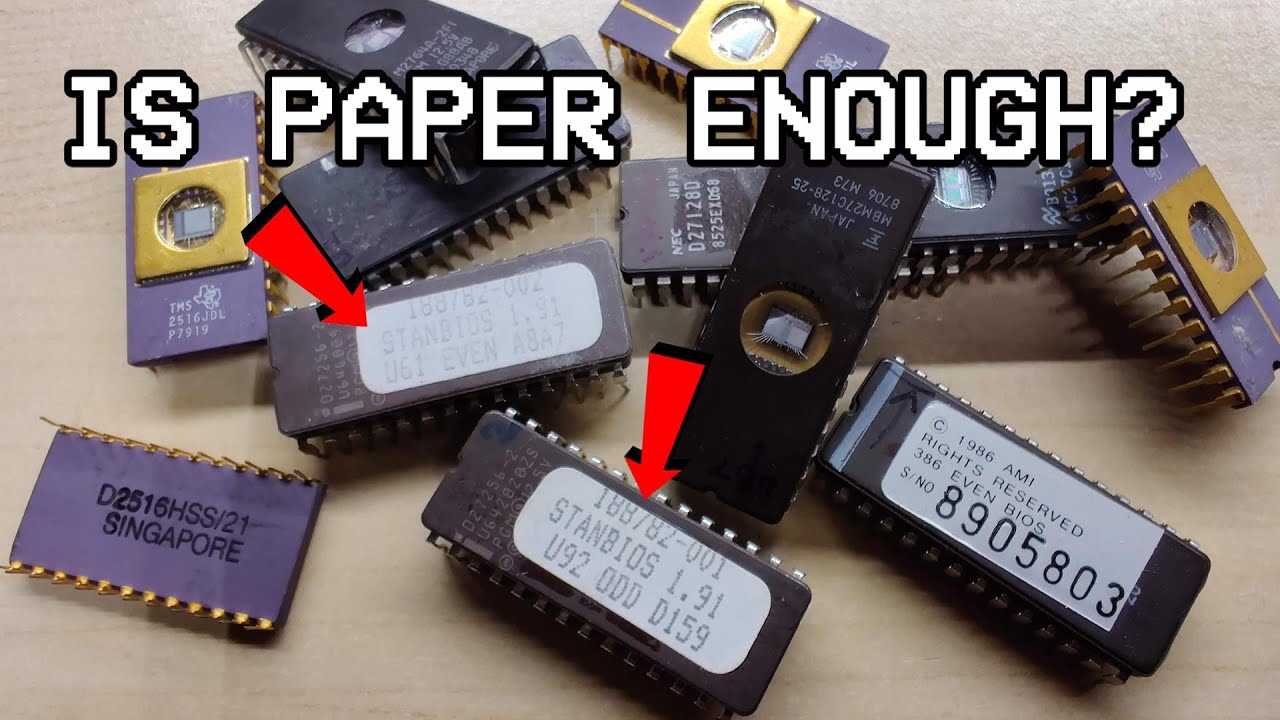

Apakah stiker kertas melindungi EPROM agar tidak terhapus?

Saya selalu bertanya-tanya apakah stiker kertas pada EPROM cukup untuk mencegahnya terhapus. Mari kita uji! EPROM dirancang untuk dihapus oleh 253,7 nm UV, yang berada di pita “UVC”. Dari Organisasi Kesehatan Dunia: “UVC dengan panjang gelombang pendek adalah jenis radiasi UV yang paling merusak. Namun, ia sepenuhnya disaring oleh atmosfer dan tidak mencapai permukaan bumi.” — Tautan Video Menggunakan matahari untuk menghapus EPROM: (dan juga menguji flash Xenon) EPROM Artikel Wikipedia: UVC di Wikipedia: — Alat Deoxit D5: O-Ring Pick Set: (Saya menggunakan ini untuk mengangkat chip dari papan) Elenco Electronics LP-560 Probe Logika: Hakko FR301 Besi Pematrian: Rigol DS1054Z Osiloskop Empat Saluran: Kacamata Pembesar yang Dipakai di Kepala / Pembesar Kepala Flip-In Lensa Ganda: TL866II Plus Chip Tester dan programmer EPROM: (The MiniPro) Besi Solder TS100: EEVBlog 121GW Multimeter: DSLogic Basic Logic Analyzer: Magnetic Screw Holder: Universal ZIP socket: (clone, digunakan pada mesin uji ZIF-64 saya) RetroTink 2X Upconverter: (untuk menghubungkan sesuatu seperti C64 ke HDMI) Plato (Clone) Side Cutters: ( pesan lima) Heat Sink: Botol-botol kecil yang diperas: (tersedia di tempat lain juga) — Tautan Repositori GitHub saya: Commodore Computer Club / Vancouver, WA – Portland, OR – PDX Commodore Users Group — Video instruksional Video saya tentang bebas kerusakan penghapusan chip: — Musik Intro musik dan trek lainnya oleh: Nathan Divino @itsnathandivino

source

The indication window on your eraser is blue. Pure UV you would not see at all. However, UV light sources based on mercury vapor emit several discrete wavelengths, some 254 nm, other 366 and yet other in the visible (to humans) range. The shorter wavelengths are more energetic and therefore are used for the UV-EPROM erasing. However, there are still a couple of issues. The 254 nm wavelength is mostly filtered by window glass, and in fact the atmosphere. You need pure quartz (or saphire) window for getting the UV-C radiation to pass through. By the way, that is also called Germicidal radiation, because it kills germs. The LED lights actually generate violet light rather than ultraviolet. However, that is still enough to make the built in fluorescent compounds to radiate more or less white light. That conversion eliminates the bulk of the violet light and the plastic housing filters much of the remainder. If there would be real ultraviolet light generated, the result would be the same, including the fact that the plastic lens does not pass much UV. The human vision has been defined to span one octave, either 390 to 780 nm or from 400 to 800 nm. The LEDs sold as "UV" LEDs are not a single wavelength (as lasers mostly are) and generally span from 395 nm to 405 nm. Depending of your chosen definition of visible range, part of the light of these "UV" LEDs may indeed fall to the UV range, while the rest in both definitions falls into violet (i.e. visible) range. Which is not too bad, because some polymerizing compounds (photo resists) actually are optimized to 405 nm radiation.

Hi Adrian, to manage my chips, the solution I opted for is tackle boxes, they keep the parts separate and come in many sizes and can be put on the bench in a pinch…

Boa noite datasheet KME-9801-4

Interesting experiment, thanks for sharing! 👍

I did an an experiment a few years ago, I left an EPROM on a windowsill, it started getting corrupted in a week. I actually did a video on it:

#182 Daylight EPROM Erasing Experiment – does daylight damage the eprom data

https://youtu.be/_vWgsZF5Ecg

That realy surprised me.

I've got the same EPROM Eraser. Did your's come with a broken timer ? Mine did. LOL.

There's no UV light down here because HEUMOHNS! EEPROMS are safe around people.

6:19 – "Close the drawer and the light STAYS ON!" – (with apologies to Firesign Theater 🙂 )

I have had a eprom that went corrupt. It had no sticker and the cabinet had an open mesh at the top and rear. It stood near a window for many years. After it failed it stood there for some years before it came in fore repair. The eprom was as good as empty, tried to get the hex file from the manufacturer but it was to old (25 to 30 years). It took long because UV is (partly ? I blocked by klass. My eprom eraser does it most times in 10 minutes. I tried erasing them on UV tubes from a face tanner but after many hours they were still not erased.

Thanks for testing this, I wondered for a while if stickers were enough, I use alu tape after programming to bre sure

I’m enjoying this video but remain disappointed that the channel is not called “Adrian’s Digital Sub-Basement” 🙂

Soviet EPROMs can be easily erased by sunlight.

Thanks for answering some questions which were disturbing me since decades. 😅👍🏻👍🏻

I always thought the stickers were to prevent accidental reprogramming/erasure, you have to explicitly peel the label off first before you can erase it.

Regular window glass blocks UV.

Within reason when worked for military any cover to window on eproms or uc with uv eprom will work.

Further worked for 8 hrs trying to work out why eprom contents changed (live in circuit). Able to see data changing from eproms as moved light across device! Devices with no "cover" ie tape etc.

Bear in mind was stone age (texas instrument eproms 2716, 2732)

I put one on that dash of my car for a full workday and didn't have any data loss. I theorized that the glass of the windshield was probably opaque to the band of UV light that is needed to erase the data, and that the window on the chip is probably a special quartz glass that passes that band.

Even the glue from the sticker on the quartz window can prevent proper erasure. Indoor visible light has not erased any prom that I've programmed and used.

Sort of irrelevant. The eprom data is only "guaranteed" by the chip maker for only ten years. Motherboards from about 7 years old start to have corrupted Bios issues. Even write once proms with no window.

I making eeprom emulator with teensy 🙂

Actually, the purpose of the sticker is to block light because light can also make faulty or partially programmed cells work!

I remember a time in the 80's when were designing and testing a computer mainboard with a programmable EEPROM with no label on the window. It was all running great, so we put it all back together and replaced the plastic lid, switched it on and it didn't work (no boot – POST fail)! So we took off the lid to see what we did wrong but it seemed to work OK again. So we replaced the lid and it didn't work! We found that just by holding the lid over the top of the system then it would stop working.

So the light was actually making the EPPROM work, if we stuck a label over the clear window it stopped working (lid or no lid).

After that, we always stuck a label on the window BEFORE we programmed/verified them!

A fluorescent tube with no phosphor is a UV light really. They will just be clear and you could see through them (safe when not powered on). These days you can get UV flashlights that might do the trick too. Of course they are not safe for your eyes either.

Imagen you open up your computer in the sun and then get distracted . You put it together and boom nothing … That would suck

Don’t most if not all commercial EPROM stickers have a metal layer in them?

Do EPROMs dream on effacive sweeps?

UV bulbs can be used up and no longer generate a wider spectrum of UV so replacing them is necessary to some extent.

Gee I wish that I could put myself through a Eraser to erase memories!

My UVC bulb broke when I ran it for a long period

Chips in your basement are all fine n dandy until that one day you're lax about it and perhaps take a take an EPROM out of your basement without the sticker

i have seen some later eeproms with stickers that just have the Winbond or SST logos under them.

I don't remember the brand or chip number but I used to erase micro controllers by leaving them on the roof of my site trailer for 8 hours. However, that was in the Shreveport Louisiana sun in the summer time. 😉

Back in the 80s I had a job of testing electronic circuit boards used for building controls. Each board had 3 EEPROMS on the front. We had over 15 test/burn-in stations all running the same building control board. Initially the boards had blue vinyl labels covering the EEPROM window. The blue labels seem to work fine until someone came in one day and took a photo using a camera with a flash attachment. Every controller started to reset right after the flash. Engineering immediately changed the blue labels to foil labels which wasn't affected by a flash camera.

No stickers are necessary if you keep the UV EPROMs inside the machine. I've tried to erase such EPROMs putting them in the full sun, and after two days chip wasn't erased. I also tried to use some UV LEDs (resin curing lamp) and it didn't worked as well.

I think you underestimate the amount of UV light that exists, even indoors.

Not every paper will protect against UV – but Paper that will glow in UV will absolutely protect, it basically converts UV to visible light and thus makes it impossible for the UV to erase the chips. Recycling paper for example might not block UV – at least not to this degree.

Whilst you are mostly right about ambient UV being a bit too weak to reliably wipe a EPROM, you made one massive flub when you said you are in a room lit by LED bulbs so there's no UV.

Why? Because there is no such thing as a white LED bulb. Well… there are, but they are prohibitively expensive to the tune of thousands of dollars per bulb.

The normal white lighting LED bulbs we get aren't white LED's. They're Blue and UV LED's covered with a yellow phosphor. In this way they are more similar to conventional fluorescent bulbs and that actually means there IS a decent amount of UV bleedthrough.

Take a decent UV flashlight out to the roadside at night and shine it down the road towards street signs. See how they illuminate many, MANY times brighter than the surroundings? Road signs are coated to fluoresce under UV to make them more visible during daylight. Any bulb putting out UV at night will illuminate the sign far far brighter than a conventional bulb.

Go into a darkened room at night that has LED bulbs, close your eyes and turn on the lights, and wait about 30 seconds. Now turn off the light and immediately open your eyes and look at the bulb. It will typically continue to have a dim glow for around 20-30 seconds. What you're seeing is phosphor decay. The cheaper the bulb the more likely this is.

So if you're using LED's, you're actually being exposed to a decent amount of UV, because again, they're not white LED's, they're blue/uv LED's + yellow phosphor. If you remember your CGA colourspace, R+G == yellow, R+G+B == white.

Man it must suck to have to live in Portland.

Thank you again for your videos. Had a refrigerator fault caused by two electolytic caps. Had to source, remove and solder the new ones on. No big deal although <$20 for the fix in 12 hrs rather than $400+ and days. Thanks again 👍👍👍

It's a quality control thing. The reason why manufactured developed eprom have a sticker is a quality step to prevent it from happening accidently(especially because manufacturing floor have have a variety of stray UV source). It is very hard to erase an eprom accidently. But if you flood it with UV the changes are almost 100% no matter the covering of the window. The one's in your shop are pretty safe from being erased.

CFL lights? they do internally use UV but im pretty sure the transmission through the glass its pretty small.

Well, I've burned 27C160s, left them untaped, for a day or two hanging around the desk, not exposed to the sun. One of the damn eproms developped a fault, had to erase and redo it. So I'd say best to cover them..

What I remember back in the day was foil stickers and mostly used as safety precaution.

My first "exposure" to EPROMs was in the late 80s when I started a 30 year career in marine electronics. I was servicing/installing JRC GPS navigators. Each month JRC would send updated firmware for their JLR-4000/4100/4200 series of GPS receivers. I had a multi gang EPROM programmer and used a UV-B plant grow lamp to erase the old EPROMS. This was most certainly the wrong lamp but it did erase the EPROMs after a few hours or so 🙂

Run them in a computer while erasing them, please.

EPROMs aren't only erased by UVC light, any light works. UVC is only much faster than other wavelengths due to having much higher energy. There is nothing special inside an EPROM that reacts specifically to UVC light. Photons strike the surface and punch out electrons (similar to a solar panel), which reduces the stored charge in the memory cells.

For a little extra insurance, I like to soak my paper in sunscreen to make super duper sure.

quartz glass in the eraser and the chip window, regular glass blocks a lot of UV anyway.

this is the first time I noticed the picture changing from orange to blue… I've been too busy watching the fingers…

There is actually some UV light coming from the LEDs. The fact is that it's 504nm which is well above the wavelength that would erase the EPROM's data. They require UV C, not UV A. A fluorescent tube designed to disinfect a room or water sistern would work but it would also give you skin cancer. LEDs just don't have the spectrum. Neither do most fluorescent tubes including the black light kind you'd find for party lighting.